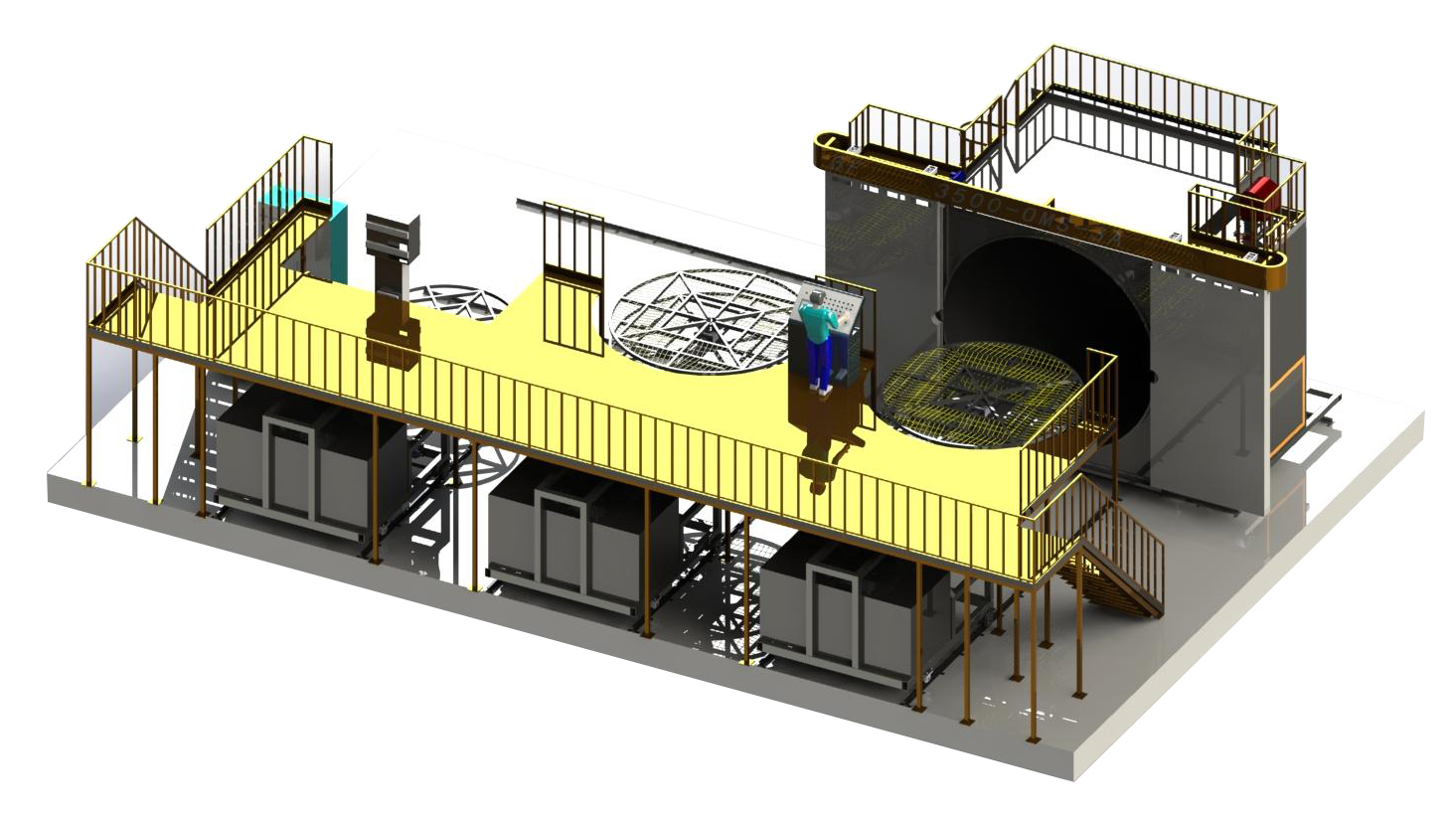

Oven Linear MovementShuttle-type Roll Bronzing Machine

Advantages:

1. High flexibility, suitable for various products, not limited by dismantling and assembling time of different molds

2. Suitable for narrow and long factories

Features:

The Oven Linear Movement Shuttle-type Roll Bronzing Machine is a machine suitable for producing products with different production process requirements, high product differentiation, small batches, and medium to large products. Continuous production is possible when changing molds, and the machine has a small footprint, making it a practical machine.

Mechanical Part:

The equipment assembly adopts modular design, which can be installed quickly.

Cylindrical oven has low energy consumption and high efficiency.

The main spindle is thickened and the reduction gearbox directly drives the main spindle to avoid the spindle shaking.

The main spindle is internally equipped with a 27mm outer diameter and 21mm inner diameter breathable pipe, which can pass through a large amount of air.

High-quality electric slip rings reduce failure rate.

Oven:

The oven temperature eliminates the previous two-stage (high fire/low fire) heating, and real-time monitoring is used to adjust the ratio adjustment valve on the combustion machine.

The temperature inside the cylindrical oven is uniform. The hot air is blown into the oven through the stainless steel swirl fan under the drying channel, and then enters the drying channel again through the suction outlet on the top.

The air flows out from the bottom and is circulated upwards, preventing materials from catching fire.

The drying channel is made of durable 2mm thick plate.

Combustion system:

Optional combustion machines (domestic Liyarou, domestic Weiru, German Weiso, American McSen),

Fuel options: natural gas, liquefied gas, diesel.

Control system:

PLC system: Delta system or Siemens system can be selected, with standardized wiring and signal direct control cabinet,

Reducing delays and interference caused by wireless transmission.

Heating program: Each arm can set three different heating temperatures, heating time, inner and outer axis speeds, and circulation air volume separately.

Cooling function: cooling time, cooling delay time, water mist (optional).

Storage function: store production parameters for corresponding products.

Main spindle and auxiliary spindle remote controller: wireless remote control for rotating arm, convenient for dismantling and assembling molds (optional).